CNC

Machining

Using the latest in CAD/CAM advanced and C.N.C machine technology we can accurately create parts at a faster pace for a variety of industries including aerospace, medical, alternative fuels, food, oil & gas, and more.

Co-Ordinate Measuring Machine (CMM)

Mitutoyo Crysta-Apex 9168

- Measuring area: X 35.63\" x Y 63.19\" x Z 31.70\"

- Renishaw: SM125-2 / SP25M / PH10MQ

- Probes: 12

5 Axis CNC Mill

Matsuura MAM72-52V

- 5 Axis Vertical Mill

- 40 Taper

- 20,000 RPM

- 25 HP

- 330 Tools

- High Pressure Thru Spindle Coolant 1,000 PSI

- 15 Pallets – Lights Out Operation

- STUPID ACCURATE, INCREDIBLE REPEATABILITY & FAST

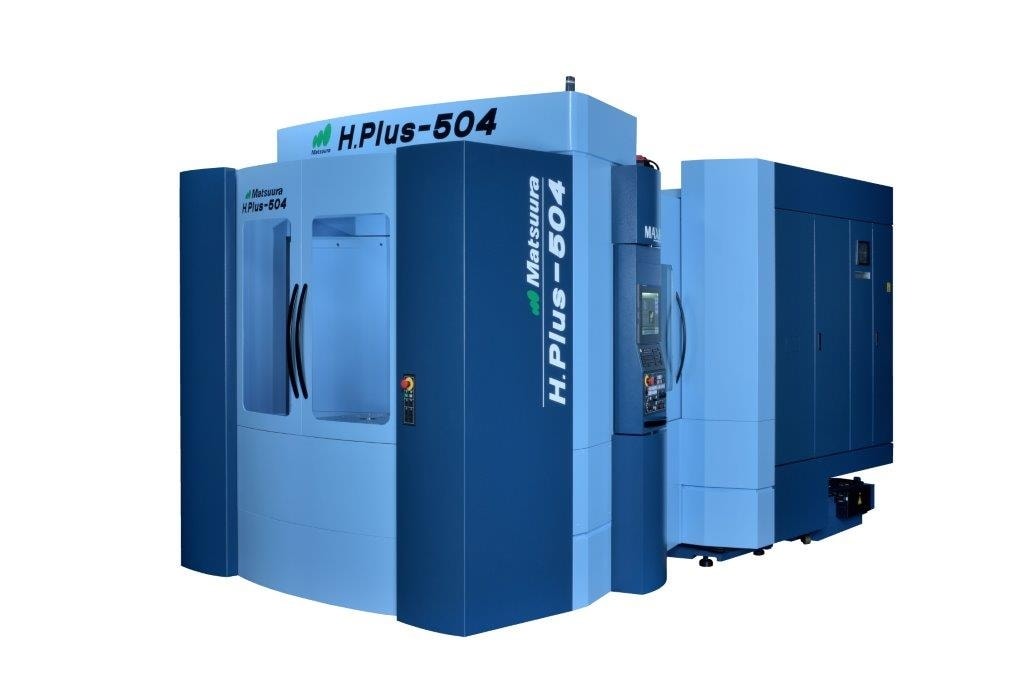

MATSUURA H+ 504 & Fastems 18 Pallet Horizontal Machining Center

- BT40 BIG PLUS SPINDLE

- 20 HP / 255 Foot Pounds of Torque

- 15,000 RPM

- 330 Tools

- X 28.74” x Y28.74” x Z31.49” – Full 4th

- HIGH Pressure Thru Spindle Coolant

HAAS UMC-1000 10 Pallet

- 5 Axis Vertical Mill

- 40 Taper

- 12,000 RPM

- 30 HP

- 50 Tools

- High Pressure Thru Spindle Coolant

- 10 Pallets – Lights Out Operation

HAAS UMC-500SS

- 5 Axis Vertical Mill

- 40 Taper

- 12,000RPM

- 30HP

- 50 Tools

- High Pressure Thru Spindle Coolant

HAAS EC1600 ZT 4 AXIS HORIZONTAL MILL

- CAT 50 Taper

- 10,000 RPM

- 30 HP

- 50 Tools

- X 64” x Y 50” x Z40” – Full 4th

- High Pressure Thru Spindle Coolant

Vertical CNC Mills

Matsuura MC-500

- 20" X 14" X 18"

- 10 HP

- 20 Tools

HAAS VF-6 Mill

- 64" X 32" X 30"

- 30 HP

- 25 Tools

CNC Lathes

Okuma Captain L370 SBM

- X, Z, C Axis - 2" Thru Spindle

- 12 Tools

- C Axis

- Programmable Tailstock

- 20 HP

Okuma Crown

- X, Z, C Axis - 2-3/4" Thru Spindle

- 12 Tools

- Manual Tailstock 25 HP

- 300 Psi

HASS ST-40

- X, Z, C Axis - 4" Thru Spindle

- 55 HP

- Steady

- Tail Stock

- 300 psi

- Live Tooling

3D Scanning Capabilities

- 3D scanning for Reverse Engineering & On-Site structure & part data capture.

- 408,000 measurements/second.

- Fast & Accurate – approximately accuracy up to 0.040mm (.0016").

- Works with our SolidWorks software for easy & accurate 3D modeling.